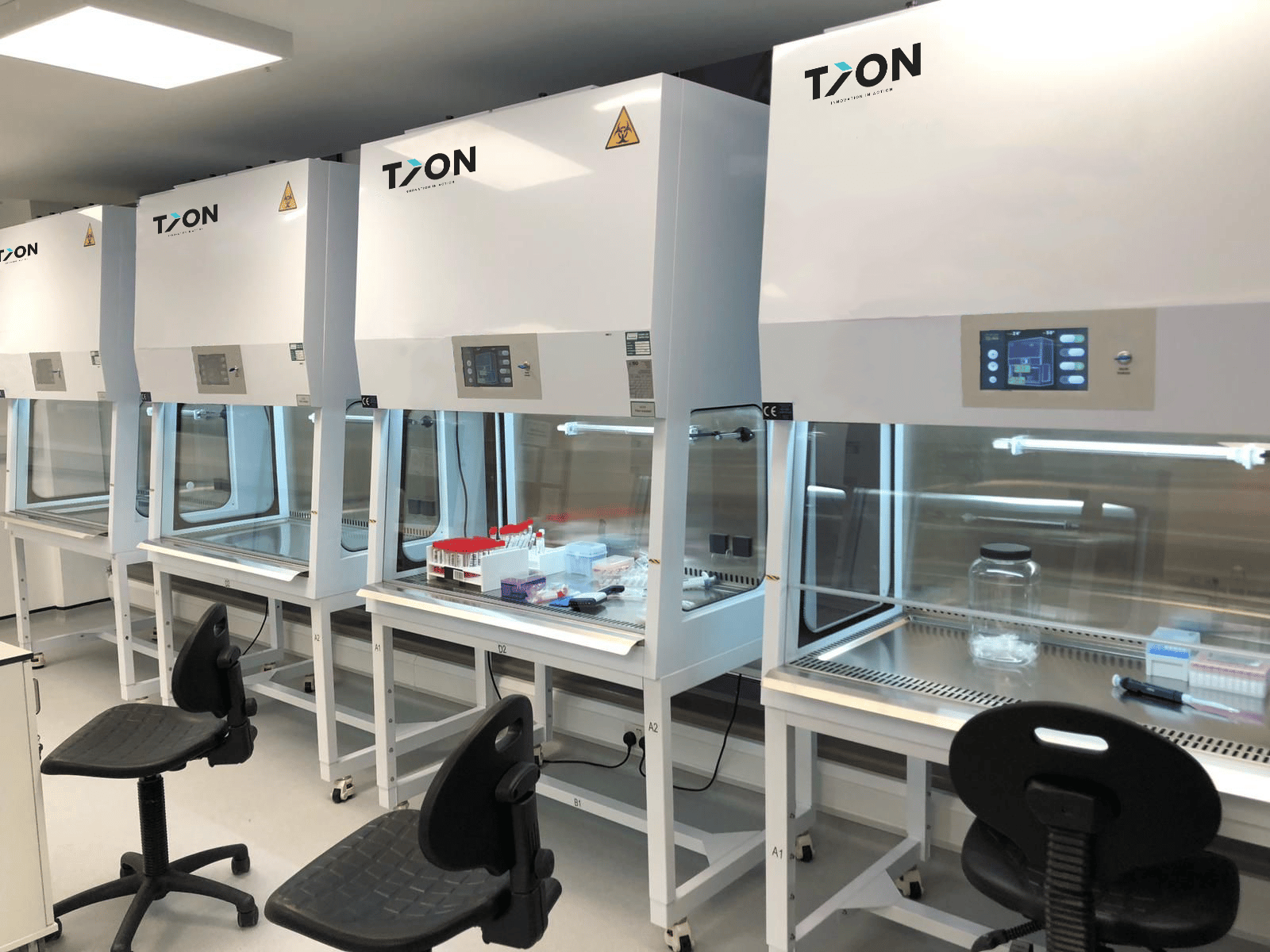

CADILLAC PROJECT: When it comes to Clean Room Manufacturer in Kolkata, Cadillac Filters Pvt. Ltd is a best choice for you.Cadillac Filters Pvt. Ltd. focuses on creating clean room environments that meet the real-world demands of pharmaceutical plants, hospitals, laboratories, and critical production areas. The company designs modular clean rooms that offer consistent control over airflow, air pressure, temperature, humidity, and particulate levels. Each solution is developed in line with USFDA, EU-GMP, and WHO guidelines to ensure safe and compliant operations.

- CGMP certified clean room design

- Full compatibility with chemicals used for cleaning and sanitizing

- State-of-the-art clean room technology

- Flush surfaces everywhere!

- Scratch-resistant materials

- Easy to modify during wall installation

- Wall system suitable for ISO 5 (class 100) to ISO 8 (Class 100,000)

Clean Room: Our Modular Wall panels are made out of Double Skin Panels of PPGI (Pre-coated Gl) on both sides with 0.6 to 0.8 mm as standard thickness. The wall panels are of 1200 mm as standard width. Panel Thickness varies from 50mm / 60mm / 80mm / 100mm with provision for PVC conduits for Electrical cables and panels of 80mm/100mm are specially designed to carry return Air Ducts / Built-in Risers. Panel height can be adjusted to 4000mm with provision for stackable panels.

Modular Ceiling Panels: Modular Ceiling panels are made up of 50mm / 60mm thickness depending upon the type of application. Ceiling panels are mounted with specially designed suspension members and linkages for every application. Additionally, they have non-shedding and non-flaking properties for a superior finish and are very easily cleanable and maintenance free best clean room panel manufacturer. Walkable & Non Walkable ceiling panels are made as per the client’s requirement with specially designed stiffening systems for walkable load-bearing ceilings.

Insulation Material:Polyurethane PUF Foam (CFC Free) with closed content of 90 to 95%.This foam is injected under high Pressure with Precise Ratio & Proportion to maintain the PUF density between 38 to 42 Kg/m3. OR Bonded Mineral wool or Rockwool insulation of various thicknesses ranging from 50mm to 100mm is sandwiched between the outer & Inner skins and is properly sealed from the exterior by Aluminium or G.I. Profiles.

Covings:All the internal & external corners of Modular Wall panel systems are covered with Aluminium covering having special Male & Female profiles with a locking system and are fixed from Wall Panel to Floor, Ceiling to Wall panel & Wall to Wall panel. Aluminium coverings are powder coated in various colours as per the client’s requirement. In addition to the previously mentioned equipment, every clean room has handheld or built-in sensors that monitor the room's particle density, making sure it is at the appropriate level. The class of clean room will determine what the appropriate particle density should be; these classes range from Class 100 to Class 10,000 and even higher. We are highly expertise in manufacturing the clean room for your use. The clean room requirement is not certain only to the medical firm—other industries like manufacturing electronic devices, automobile devices, and food ingredients. We are not any normal manufacturers who are building up below than average material used clean rooms.